For more information, Please call us

0086 18340048768

Give us a message

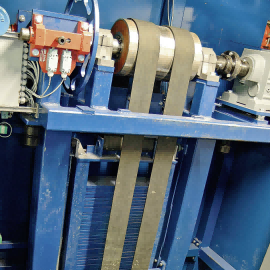

Message >>This type of conveyor system is equipped with automated controls, sensors, and a motorized drive mechanism that allows it to function without constant manual operation. It can be programmed to perform specific tasks such as picking up items from one location, transporting them, and depositing them at another predefined spot.

These conveyors are utilized in manufacturing plants, warehouses, distribution centers, and other industrial settings where there is a need for automated and controlled material handling between different points within a facility. The automation of these systems helps in streamlining operations, reducing labor costs, and enhancing overall efficiency.

|

|

|

Features:

1. Tailored to your precise application requirements with customized design options.

2. Capable of handling heavy loads exceeding 15,000 lbs. Standard carriage sizes extend up to 15’ x 15’ or larger. Vertical transportation spans up to 200'. Adjustable speeds to align with your specific throughput needs.

3. From straightforward two-level setups to intricate multi-level configurations, adaptable to diverse operational needs.

4. Versatile multi-directional systems facilitating both vertical and horizontal conveyance, offering adaptable loading/unloading patterns.

5. Horizontal conveyors engineered to match load specifications, weight capacities, dimensions, and throughput demands.

6. Available options include tilt-deck, roll-handling, and cart-handling systems for enhanced versatility and specialized material handling solutions.

|

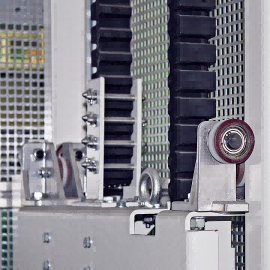

1. Secure transportation interlock system: Utilizes a safety interlock system to ensure the secure and stable transportation of goods |

2. High-precision positioning driven by servo motors: Employs servo motor-driven systems for achieving precise and accurate positioning of goods. |

|

|

|

3. Anti-spillage device for goods: Incorporated safety mechanism to prevent sudden spillage or displacement of goods during operation. |

4. Motor overload alarm during operation: Features a monitoring system that detects motor overloads and issues alarms to prevent equipment damage or ensure operational safety. |

|

|

Our Service:

1. Free 3D Design:Based on years of experience and expertise, our in-house team of senior design engineers can work out the best suitable lifting solutions for you. Free design of hydraulic lifts will be provided based on your work requirements, sites and budgets.

2. 7*24 Online Service:From pre-sales service to after-sales service, our professional engineers and sales team are always ready to offer customized suggestions and solutions for your lifting requirements. 24/7 Online technical support is available.

3. Warranty: All products are provided with 1-year warranty. Free parts will be sent to you if there is any problem caused by non-human factors during warranty time.